Intro.

I know, I can hear you, “it’s just a knife handle, what’s the fuss about”? In many ways you’d be right, whatever handle the knife comes with is fine right? Up to a point, yes, however there are a few things to look out for if you are serious about the longevity and practical functionality of your Knife.

Along with half of the knife-making fraternity I’ve been messing around with different knife handle material for a long time. I’ve tried making and using my own Micarta, I’ve tried many different types of wood including stabilized and non stabilized, G-10, and materials I’ve found lying around the workshop.

If you are a knife-maker there is one thing advantage to being fussy about handle material (or ‘scales’ as they are usually known as) and that is it gives you some unique attributes to the design of your knife. You can even make the color as part of your business identity. Making your own handle scales does that for you. If you get it right it’s well worth it.

In this article I’ll try to explore as many types of materials used for knife scales and perhaps explore the positives and negatives of them. Keep reading I hope you enjoy the article.

Here are the Most Common Materials.

- Wood

- Bone

- Antler & Horn

- Metal

- Micarta/G-10/Carbon Fiber

- Plastic & Synthetics

- Paracord Wrap

- Other Natural Materials

Types of Wood.

How many species of threes are there? Ha, according to some data sets it’s estimated that there are roughly 60,000 to 80,000 species of trees globally. Well, if you have a couple of decades to spare I can go through them all and see if they are any good for Knife Handle Scales :0)!!

The point is of course that there are so many to choose from that you could put a different type of wood on each new knife you make and never run out of different species of tree wood to use. The most important aspect of using wooden handle scales is whether or not it’s stabilized or not. We can also look at the density of the wood and this has an impact on the hardness of it and it’s ability to soak up the stabilizing resin. Let’s digress for a moment and talk about the stabilizing process.

- Put simply this is a process whereby a type of resin is forced into the fibers of the wood under pressure and left to cure. This produces a solid piece wood that is impervious to water and the regular decay you might see in wooden products.

- What they do is place the wooden blanks in a vacuum chamber whereby the air is pumped out to remove remove it from the porous structure of the timber fibers allowing the resin to penetrate into it.

- There are a few types of resin such as a 2 part epoxy or an acrylic solution. One type of resin nearly all knife-makers have heard of if not used themselves is one called Cactus Juice. This not juice sucked out of a cactus plant. It’s a solution originally derived from petroleum refining which has a composition made up of ‘methacrylate ester monomers’ the easiest way to make sense of this name is it is to say often used in products such as plexiglass. It has a low viscosity making it easier to penetrate deeper into the wood.

- When this process is completed it makes the wood very hard wearing, strong and resistant to decay and protect it from various forms of moisture attack. It sand so nicely and all it requires after shaping is buffing up to a glossy finish.

Here in Perth Western Australia I like to use a local wood that only grows here, it’s called Jarrah. It’s super hard wood and quite frankly hardly needs resin stabilizing but we like to do it anyway. Most of the hard woods like rosewood, cocobolo, and ebony are used widely due to variations in their beautiful colors and grain.

Bone Material.

- Camel bone is sometime used because of its unique color and texture. Camel bone handles vary in color from ivory white to beige and even orange tones. They are durable and very resistant to wear and tear…not cheap though!

- Cow bone, as we would expect this is a cheap alternative. Each year in Australia alone, somewhere between 7 and 8 million cattle are slaughtered, that’s a lot of bones! It’s pretty versatile stuff. You can polish it to a glossy smooth finish, tone it down to a satin look or texture it quite easy. Cow bone durable and affordable, check some out when you have a minute.

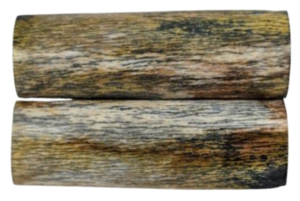

- Giraffe bone has an amazing look to it, I used it on one of my custom builds.

- You can see by the picture that it’s almost got a timber like grain running through it. It ranges from a more plain white grain through to a spotted, mottled look. Some are dyed with many colors to choose from. Along with other bone and horn products it’s very hard wearing. This makes it quite unique. Knife nerds and collectors love it.

Antler & Horn Material.

There is a ton of this out there. You make your choice and stick it on your knives. Just imagine, every year animals are growing new handle scales for us, so nice of them eh :0)

Thanks mate, looks like you have already donated at least one set of handle scales, cheers :0)!

This material has been used for thousands of years. There over 50 species of deer alone, including white-tailed deer, elk,, moose, red deer and reindeer. Then there are the choices of Horn material like cow, sheep and buffalo and the list goes on. It’s really good material to use and is sustainable if harvested in the right way.

Here some Handles Scales growing on this Aussie Highland Cow!

Here some Handles Scales growing on this Aussie Highland Cow!

Being a natural material that grows on an animal it has some ‘give’ in it which allows for a certain amount of shock absorption. Made from Keratin they are very strong and resistant to moisture. The aesthetics if it lends itself to certain blade types like Bowie Knives. It seems to fit nicely with the thoughts of going into the wild on a hunting trip with a Bowie adorned with elk antler scales, strapped to your side.

Metal Handles.

Anodized Ali Handle is often a metal of choice

Anodized Ali Handle is often a metal of choice

One of the drawbacks with metal handles is the weight of them. Depending on the weight of the blade the knife can be back heavy creating an unbalanced experience. Although Titanium & Stainless Steel is used the majority use Aluminum. They are often anodized to interesting colors. As you would expect they are very resistant to all of those undesirable affects that lesser materials might bring. They can be textured and shaped as well as any wooden or composite material. I do know they can be a little uncomfortable in extreme cold conditions. They take a while to warm up compared to Antler or G-10 for example.

Composite Materials.

Here is an example of home made Micarta.

Here is an example of home made Micarta.

From making my own Micarta to Carbon Fiber I’ve used just about all of them at some point in my knife-making career. If you make your own Micarta you’ll soon realize it’s a very messy process with mixed results. You can end up with wedge shaped blocks full of holes. If you do this be sure to experiment a lot and be prepared to use up lots of resin before you stick it on one of your knives.

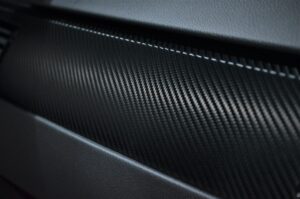

Carbon Fibre is a common choice these days. It looks modern and has that interesting light interference depending on what angle the light hits it at. It’s light and impervious to a lot of those nasties a knife handle is affected by.

Carbon Fiber Material

Carbon Fiber Material

For me I usually end up going back to G-10, it’s made well, heaps of colors to choose from and carries all of the pluses we look for. Resists impact, impervious to most chemicals, moisture resissant & very grippy even with light texturing.

G-10 Material

G-10 Material

Plastics and Synthetic.

These materials seem to fit mostly into the affordability range. They are cheap to produce and the sources are almost endless. I’ve even used layers of white acrylic material to simulate an ivory affect as in the handle of this dagger I made.

The choices range from ABS plastic, Nylon, Polymer Blends of all descriptions. They may not be as hard wearing as Deer Antler or G-10, but it’s practical and functional and does the trick on a budget blade.

Paracord Wrap.

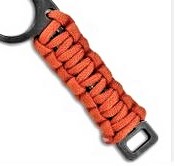

Typical Paracord Wrap fitted directly to the blade tang.

Typical Paracord Wrap fitted directly to the blade tang.

As you would know there are oodles and oodles of colors and thicknesses of this material to choose from. It’s applications are far and wide. A well known knife-make wraps the handle and then coats it in a resin. The result is a grip level that probably cannot be surpassed. With this treatment it’s very hard wearing and can boast a long lasting alternative solution to handle scales. Here is one of my builds on a modern take on a Tanto Knife.

Modern Material, Traditional Style!

Modern Material, Traditional Style!

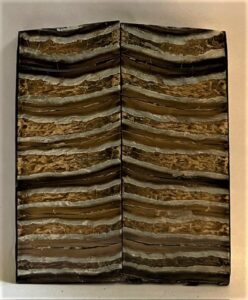

Other Natural Materials.

There are plenty of other materials to use if you so desire. There is a fairly well known You Tuber who built a knife out of a shovel and Concrete, concrete being used for the handle material. Although I’d steer well clear of using concrete it does show how diverse you can be when choosing handle material. I’ve known various kinds of Stone to be used, again not recommended as they are far too brittle and a bit on the heavy side. Mammoth Tooth can also be used. As far as I’m aware mammoth teeth are all really fossils out of the Pleistocene era. In that case it’s really stone like material. It looks good but not sure about its effectiveness as handle scales.

Mammoth Tooth.

Mammoth Tooth.

There so many others you could use. Leather is a great choice, it has that natural look we all love. Then there is Mother of Pearl (mainly for inlays) Coconut shell, Bamboo ….. shall we go on? Suffice to say there are plenty of choices. The sky’s the limit as they say.

Conclusion.

Needless to say but choosing the right handle material plays a part not only to it’s functionality but also in the aesthetics of the final piece. The intended use of the knife will determine which direction you’ll take. A light use knife will give you a wider scope of materials to choose from. A 4 week survival adventure will need the hardest wearing material you can find (Antler or Cow Bone perhaps). So there you are, the aesthetics and the intended use will eventually steer you in the right direction whether buying a knife or making your own.

There is one fact often overlooked when it comes to knife handle scales, and that is it gives you a uniqueness that, in almost all cases where a knife-make builds his or her own knife with natural handle scale material it’s almost guaranteed that no-one else on the planet will have done exactly what you have done. It can be part of your identity as a knife-maker. So good luck with it.

As always happy camping :0)