Many years ago I started my working life back in England at 16 years old in a family butchers shop and immediately became embroiled in the world of knives. One of the most important things we would do on a daily basis was sharpen our knives on a stone, make sure our honing rods had a good clean up from the previous day and we were ready to attack the day. It was an important skill to have and create the habit of religiously doing this each day.

The ‘Honing Rods’ or ‘Steels’ as we used to call them, were big old fluted hardened steel rods that seemed to last years. These days they come in all shapes and sizes. This article looks into different types of honing rods, how to use them, which one is perfect for the job.

Honing rods, what are they?

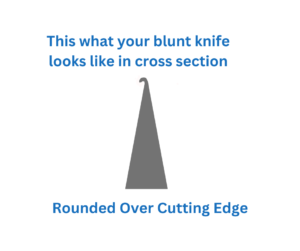

A Honing Rod is basically just a fine abrasive surface that’s harder than the cutting edge of the steel it’s trying to sharpen. I say ‘sharpen’ but actually it’s really just taking out some of the rounded over cutting edge apex. I’ve drawn this sketch to explain what’s happening on a small scale, this will help you understand the function of a honing rod and how to get the best out of it.

You can see from the sketch that the very apex of the cutting edge it gets rounded over with use, the harder the material you are cutting the quicker that edge will ’round over’. What the Honing Rod or Steel does is get the round overs to stand back up restoring the cutting edge. Well, that is partly restoring it. You’ll never completely restore the edge but it goes some way into doing this. This is why they are used during the process of doing the work. It’s a kind of temporary fix until you can re-profile the cutting edge back to it’s optimum geometry. If you go to a family butcher you might see the butcher use the Steel hanging from his apron just before he cuts a nice piece of Fillet Steak. It gives him a nice clean cut.

What Materials are Honing Rods made from?

- Carbon Steel

- Hardened Chrome

- Ceramic

- Diamond Coated

Steel Honing Rods.

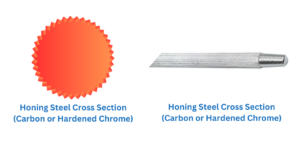

These are the most common honing rods and probably the oldest in design and manufacturing. It is produced by selecting the right kind of steel, in this case High Carbon Steel. It’s heated to forging temperature and then rolled in a machine to form these long fine ridges that form the apexes which will eventually do the work of re-aligning the edge. Just like any hardened steel product they are worked into their final shape etc.. and then hardened in a heat treat process.

You can see from this cross section what’s going on in the manufacturing process. It has these little apexes running along the length of the rod. By rubbing the cutting edge along it we can straighten out the rounded over sections and to some degree bring the edge back to a functioning blade.

Hardened Chrome Honing Rods.

Hardened Chrome honing rods are very similar in their design and manufacture but have used a carbon steel with plenty of the element Chromium in it. I would, at least, choose a Hardened Chrome Honing Rod.

Ceramic Honing Rods.

There are something different entirely. They are made from a variety of materials but mainly Zirconia or Alumina, these elements are very hard and durable, hence the ability to help straighten the rounded over blade edge.

They are produced by shaping the ceramic material into their final shape, and just like a carbon steel product they are hardened in a kiln. We know a ceramic product is ‘fired’ and left to cool as you would a ceramic plate for example. This ‘fired’ rod is then the finished honing rod after it has a handle added. They are used in exactly the same way as a carbon steel one is used.

They are produced by shaping the ceramic material into their final shape, and just like a carbon steel product they are hardened in a kiln. We know a ceramic product is ‘fired’ and left to cool as you would a ceramic plate for example. This ‘fired’ rod is then the finished honing rod after it has a handle added. They are used in exactly the same way as a carbon steel one is used.

Diamond Coated Honing Rods.

These are among the most expensive. The process to create one of these honing rods is different again. What they are is a base material that the Diamond Particles are fixed to. The base is usually a metal one and one which is also pretty hard carbon based metal.

The Diamond Particles can be fixed using various methods. Chemical or Vapor deposition can be used. However Electroplating is probably the most common way to do it. Put simply this process is created whereby the base metal is placed in a liquid containing diamond particles which have been suspended in it. Once an electrical current is passed through the liquid the diamond particles will adhere to the base metal surface.

The Diamond Particles can be fixed using various methods. Chemical or Vapor deposition can be used. However Electroplating is probably the most common way to do it. Put simply this process is created whereby the base metal is placed in a liquid containing diamond particles which have been suspended in it. Once an electrical current is passed through the liquid the diamond particles will adhere to the base metal surface.

It then goes through a process of polishing to achieve the surface smoothness or grit they are after.

Camping, Bush-Craft and Hunting Knives.

Seeing as these are much smaller than a kitchen knife it makes sense to get hold of a small one to keep in your camping bag for use in the field. Something like this one is perfect, I have one myself. This one is the ‘Accusharp Diamond’ pen style, check it out for yourself here.

The Motion to use for Honing your Knife.

If have a close look at the video above, you can see the motion he uses to hone his knife.He takes his time and runs the blade down one side and then the other. As the knife moves down the rod he draws it across the rod. It’s because the rod is on an angle he can draw the knife across it rather than straight down it.

Sometimes it only takes three or four strokes either side to get that slight edge he’s after. Other other times he might give it ten or twenty strokes until he’s happy with it.

It does take a bit of practice but what this fella is doing is the correct way to learn. Once you have learnt and doing it right you can then try other ways to do it to find the perfect way for you.