Intro.

Until I got into knives and knife making and then progressing on to becoming a knife nerd I had no idea how important this subject is and what effect it has on the performance of a knife. What determines the the edge angle or geometry as we tend to call it, is it’s intended use, blade thickness, type of material and type of grind. I’m aware that if you are not a knife maker you won’t have any influence on what grind the knife comes with, unless you are engaging a custom knifemaker to make you one. However, knowing which type of grind is designed for what intended use will help you make a wise purchasing decision.

So, if you are keen to buy a good quality knife and want to it for years to come, understanding these principle and applying the them is vital for the longevity of your knife, its cutting ability and optimum edge retention.

The Geometry.

Obvious to say really but when we talk about geometry what we mean is the angle of the blade blade edge, the actual cutting edge.

The angle at which the cutting edge is formed is everything. Once we know what the knife will be used for most of the time we can apply the correct angle. A lower or shallower angled cutting edge, typically between 10 to 20 degrees, results in the ability to create a sharper edge, making it perfect for precision tasks like cutting Sushi or filleting fish. On the other hand, a higher angled cutting edge, around 25 to 30 degrees provides greater durability, but less able to perform those delicate tasks as described. On the other hand it can perform heavier-duty tasks like chopping through wood or cutting through animal bones. A cutting edge with these angles will last linger before sharpening is required.

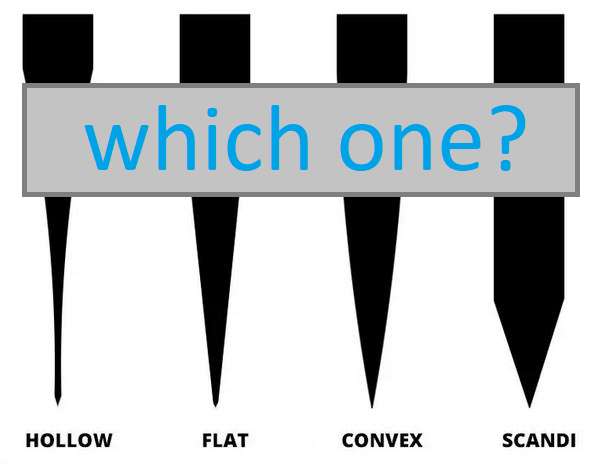

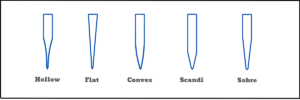

Here are a few of the most popular cross sections of knife blades. There many more designed for specific needs but these are the most common ones.

The grind of the blade during manufacturing is a critical aspect of knife edge geometry. The ‘grind’ refers to the way the blade is shaped to create the cutting edge. As you can see from the images there are many to choose from, each has its unique advantages and disadvantages.

The Hollow Grind.

This features a concave surface on both sides of the blade, we can achieve a very fine edge for delicate kitchen duties. It also helps to minimise the affect of the meat, fish or vegetable sticking to the blade. However, this kind of grind will not last long if you try to cut through some wood with it.

The Flat Grind.

This involves a straight taper from the spine to the edge, this creates a reasonably good balance between sharpness and durability. It will still have a micro bevel right on the cutting edge but is still classed as a flat grind`

The Convex grind.

With a rounded rounded edge, blades with this kind of grind are incredibly durable. They can take on some of the heaviest cutting tasks and win.

The Scandi Grind.

As you can see these cutting edges have a single steep bevel that meets at the very edge, these are quite easy bevels to maintain and designed as an all round multi task kind of blade most often added to a bushcraft knife.

The Sabre Grind.

This is similar to the scandi grind but has a shallower angle and deeper bevel to it which means we can achieve a sharper edge but a little less robust than the scandi grind. It’s also designed for a multi use scenario.

The Chisel Grind.

The blade grinds can achieve a very sharp edge. If you think of a woodworkers chisel you’ll picture just what you get with a chisel grind. As the name suggests there is a single bevel starting at a a point approximately 1/3 of the way down the face of the knife right to the apex of the edge. These are designed for specific cutting tasks, mostly associated with kitchen work like cutting Sashimi.

Aesthetics.

This worth a mention. Seeing as I’m a bit of a knife nerd I want each knife I buy to look good. This entirely a personal choice. I won’t let it negatively influence the importance of what I need this knife for but if possible I;ll look for a long-time to find the right looking and hopefully performing knife.

Maintaining The Edge.

I have written articles on the subject right here, but having a simple little sharpener of some sort will be very useful. My recommendation for this is the Victorinox Pocket Knife Sharpener. It’s a ceramic stone honing rod. Learn to use it, you’ll love it.

Trade Off.

Ultimately, it’s the balance of all of these elements that play their part in creating the perfect edge angle or geometry. Actually there is no perfect cutting edge that will suffice for all tasks. There is a perfect edge for a specific task but not one size fits all kind of answer. As a person interest in knives grows so does your understanding that the whole idea of a well performing knife is something of a trade off from one blade material against another, or one type of edge geometry over another, or one type of handle material over another.

If we choose a knife which has less harden-ability it might not retain it’s cutting edge for so long but it’s more likely to be more resistant to breaking or chipping. If we choose a hollow grind and take it on a camping trip where bush craft tasks are most used it will perform nicely for a short time and then fade quickly. But if we took a Scandi or Convex ground knife with us on that same trip we would see the performance start at a lower level in the sense of slicing ability but it will not fade as the general bush craft tasks like cutting firewood are being undertaken. This blade will not fade for days and days.

In Conclusion.

You can see the complex nature that come into play when the question “what is ‘The Best Knife Edge Angle (geometry) is asked. There is no, one simple answer. It depends on this & that & those & these! I the idea of getting hold of the ‘perfect knife’ is both an art and a science. Us nerds will always be enthusiastic about new designs & new steel etc… but the knife edge geometry will always be one of those things that will never change.

As always, stay safe and happy camping.