Check out this post I did on YouTube.

It outlines the issue of price, quality and how knife manufacturing companies should be worried.

It outlines the issue of price, quality and how knife manufacturing companies should be worried.

As I start writing this blog I realize this is the second time I’ve picked a Civivi Knife for Midweek Knife in Focus.

Its a rather strange looking knife with these black and white striped G-10 handle scales that go across them from side to side instead of longways. I can’t decide if I like it or not. It might be handy if you were to skin a bumble bee perhaps :o) Along the edge of the scales there are what I guess we can call jimping. Apparently it’s very grippy!

It has a dagger shaped blade but it’s called a ‘spear point’. The blade is ground in such a way that it looks like a dagger. It also has 6 little notches sideways across it just for aesthetics I guess. One thing that looks odd is the thumb stud is placed on a flat section of blade that should really be ground back further into the ricasso area to make it look more like a dagger. For me why bother with a thumb stud and a flipper, if they ditched the stud then the blade could be ground back for symmetry, it would look so much better.

What I can say that is very good for a US$91 knife is that it has Nitro-V for the blade steel. By all accounts this is very good blade steel. New Jersey Steel Baron say the edge stability is similar to AISI 52100, also known for being able to create fine cutting edges and is really a modification to AEB-L. I did some testing shown on my YouTube channel. I couldn’t get the steel past about 58 Rockwell but then again my set up is pretty basic. Once again for a knife that’s US$91 it has an awesome blade on it.

The CIVIVI RS71, designed by Robert Saniscalchi, has a mean dagger profile, a grippy handle, and great opening action. The single-edge blade displays stylistic grooves and can be deployed with either the flipper tab or thumb studs. The machined pocket clip lives on the right side of the knife for right-handed users. Choose the RS71 if you want a hard-sure blade with a stand-out design.

William Wallace, just the mere mention of his name conjures up scenes from Mel Gibson’s Braveheart Movie. He has reached legendary status, in part because of the movie. I’ll explore who William Wallace was and try to shed some more light on his sword, now known as ‘The Wallace Sword’, and the possibility of it playing it’s part at the famous Battle of Stirling Bridge.

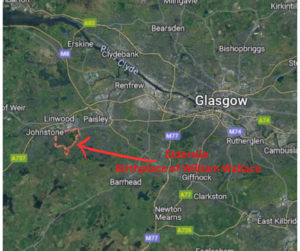

William Wallace was born in Elderslie, a village in Renfrewshire, about 15km West of Glasgow. Exactly when he was born wasn’t documented but according to history it must have been somewhere around the mid to late 1270’s. This would have put him in his 20’s at the battle of Stirling Bridge.

You can see by this map that the battle wasn’t far from where he was born. Actually it’s about 33km North West of Glasgow. If you were in Perth, WA, that would be like traveling from Perth to Quinns Rocks, or for our cousins in North America twice the distance from LAX to downtown Los Angeles, for punch up! :0)

All this took place in the late medieval era when Scotland was mostly still living with a feudal existence. There were kings, Knights & Lords romping around the place exerting their authority over people. They had control over big lumps of land and pretty much ran the show.

The clergy of the day had a bit of a say but nothing in comparison to the nobility and then there were the peasants who, just like today, were working the land and doing various trades, they had no say in the matter of social and economic rules and regulations.

At the time of The Battle of Stirling Bridge (1297) and beyond into the late 13th and early 14th centuries was time of Political Punch Ups. The war for Scottish Independence seemed to be the cause of most of this disharmony among it’s citizens. Disputes over land often created skirmishes between Scottish and English forces.

King John Balliol was in charge of things at the time of the historic battle at Stirling, but during the 40 to 50 years prior to Balliol waving his fists around, King Alexander III was making the decisions of the day. He seemed to have a lucky time of it when Scotland was going through a bit of an academic streak. There were chroniclers, poets and literary people recording history as they saw it. It was regarded as a time of stability, a time for people to take a breath and regain some composure within society.

We can’t talk about Scotland without mentioning the role of religion. This is not something I’m particularly interested in but it’s still important in the story of William Wallace. Christianity was in full swing playing an important role in peoples lives. At this time the church had a lot of power and influence to society. People were very aware of the connection certain Christian leaders had with the political figure heads of the day. As well as people needing spiritual guidance, the churches, monasteries and abbeys were there to provide various areas of teaching and encourage peoples devotion to certain religious practices, to encourage piety within the population.

As already stated this era is within the late middle ages period. Things were slowly changing at this time. Generally speaking the middle ages is regarded to have started at around the fall of the Western end of The Roman Empire and went through until the start of the Renaissance of the 14th century.

At the turn of the 1300’s it was all happening in Scotland, feudalism was alive and well, there were kings trying to gain more power, landowners grabbing more land, politicians like Robert the Bruce were also on the scene having their say for their independence from the English. Your average folk like farm laborers and Jo Blow the market trader were trying to scratch a living in amongst it all.

As time went on into the 14th century the Catholic Church began to gain traction and power, artists flourished as time saw an evolution from a medieval to a renaissance culture.

Somewhere around the mid 1280’s to mid 1290’s a blacksmith/bladesmith/swordmaker lit his forge with a special task in mind. He was to make a sword that may well find itself steeped in history and become part of a legend. The sword was to be made for a special warrior, William Wallace.

He toiled night and day. He carefully forged the steel into a sword with a 4 feet 4 inches (132 cm) cutting edge. He wanted to make a perfect sword for a warrior who was going into battle at Stirling Bridge. William wanted a blade which was 2.25 (5.7 cm) inches at it’s widest, at the guard area and he wanted it to be .75 inches (1.9 cm) wide at the tip. William also wanted it to be around 5.95 pounds in weight (2.7 kg) so he could get a good swing at the heads of those English soldiers. The total length of the sword including a two handed hilt is 5’4″ inches (163 cm). It turned out perfectly for William.

… ha, as you will know I have taken a little artistic license here. Actually nothing is known of who made the sword. Moreover, there is great doubt about whether or not this sword was actually used by William Wallace at the famous battle. Historians and experts have stated various scenarios regarding the history of the sword but there is very little written about it.

The seem to be two written references that survive which mention The Wallace Sword. One in 1505 and another in 1875.

The one in 1505 states that at the request of King James IV of Scotland an armourer was engaged to replace the wrap or binding of the hilt and make a new pommel, scabbard and belt. For this apparently he was paid 26 shillings. Whats that worth in todays money? Apparently, according to National Archive Currency Coverter, in 1510 26 shillings could buy two cows. Assuming they are fully grown cows this would be worth over AU$1000 in todays money, that’s quite a bit of cash eh!

One reason put forward for the hilt binding to be replaced with silk is because after Wallaces Victory at The Battle of Stirling Bridge, he used the skin of Sir Hugh de Cressingham and bound his hilt and scabbard with it and also made the swords belt from it.

Really? Well this is what the legend seems to be saying. However I doubt that, if any of you have done leather-work you would know that it’s possible to use human skin to ‘wrap’ something with it, I may be wrong but I very much doubt that a belt could be made from it.

A website run by The Wallace Monument seems to think the sword was kept in Dunbarton Castle until King James showed up and ordered the repairs to be done.

Side Note of Personal Interest: Sir Hugh de Cressingham was working for the English administration based in Scotland at the time. He was an advisor to John de Warenne, the 6th Earl of Surrey. This is the very same Shire in the UK that i’m from :o)

There are written records which state that the sword was sent to the tower of London to be repaired. All I can find regarding the repairs seem to be that the fittings added in 1505 were removed and handle typical of the 15th century added.

The guard, quillon & pommel are described as being made of steel. In that case it’s probably made of the same steel as the blade. There are many quillons on swords that are made from wrought iron it could be the case with Williams sword, to me it looks like different steel as it has a different color. The handle has a base material of wood but there is speculation as to whether there was originally some kind of wrap around it or left as a wood finish. The blade itself is undoubtedly made of carbon steel.

Here is where a shadow is cast over the Wallace Sword and was it used at the legendary Battle of Stirling Bridge? Here’s the thing, the quillon, guard & pommel may well have been entirely replaced in 1505. Some experts say that the blade seems to be made up of 3 separate pieces of steel forge welded together at some point in it’s history.

So if the guard, quillon & pommel have been added or are replica parts from the original and 2/3 of the blade isn’t the original blade what do we have left? What we have left is not really William Walaces Sword! Perhaps the wood on the hilt is original!

For me even if only 1/3 of the blade is original and it was present at The Battle of Stirling Bridge, perhaps William Wallace himself has wielded that part of it over the heads of English soldiers, that’s enough for me. Being more pragmatic about it, it’s what the sword represents rather than incessantly trying to prove it’s provenance at the many battles William Wallace is meant to have taken part in.

One day I shall travel to the Wallace Monument and see for myself what spirit lies within the glass case of that famous sword.

As allays, happy camping :o)

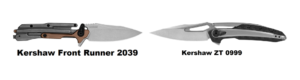

This week we are profiling a Kershaw Frame-lock Folder. It’s has a tactical look to it with a touch of brown G-10 in the handle design. It’s supposed to be based on the ZT 0999, but for me it doesn’t have the stylish look that the 0999 has. Let’s have a look at the specs a see if we think it’s worth the AU $184 it’s currently being advertised for on Australian Knife Sales.

I’m a bit of a fan of the ‘ZT 0999’ so I thought the ‘Front Runner‘ would would be quite similar. The Australian Knife Sales website states that it is ‘inspired’ by the ZT0999 so though it would have some of that sleek sweeping design. I thought it might have the ergonomic appeal. But actually it’s nothing like it.

Instead it has a tactical looking handle with brown G-10 pieces added which aren’t the same on both sides, the blade doesn’t have that hole or void above the ricasso area, there is jimping on the Front Runner and not on the ZT 0999! Don’t get me wrong it’s not a ‘bad’ looking knife but really nothing like the ZT. So I really don’t know why it’s inspired by it.

I didn’t expect the blade to be made from CPM20CV, D2 is good blade steel but is not so resistant to corrosion. D2 blade steel is often called a ‘semi-stainless’ too steel. However, the blade is shorter than the ZT. They say it’s as smooth as butter with it’s KVT ball bearing washers.

For me the jury is out on this one. I guess it’s all down to personal preference but if I wanted a Kershaw blade and wanted to spend around the AU$180 mark, I’d get the ‘Bareknuckle 7777 which a better blade steel 14C28N. Or perhaps the Highball XL 7020 which is way cheaper at AU$145 and comes with the same D2 blade steel. For me both of these knives look so much better.

Anyway, that’s what I think.

As always, happy camping :0)

Many years ago I started my working life back in England at 16 years old in a family butchers shop and immediately became embroiled in the world of knives. One of the most important things we would do on a daily basis was sharpen our knives on a stone, make sure our honing rods had a good clean up from the previous day and we were ready to attack the day. It was an important skill to have and create the habit of religiously doing this each day.

The ‘Honing Rods’ or ‘Steels’ as we used to call them, were big old fluted hardened steel rods that seemed to last years. These days they come in all shapes and sizes. This article looks into different types of honing rods, how to use them, which one is perfect for the job.

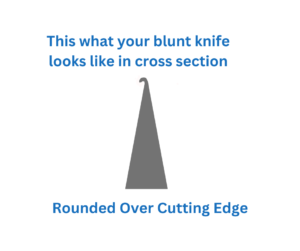

A Honing Rod is basically just a fine abrasive surface that’s harder than the cutting edge of the steel it’s trying to sharpen. I say ‘sharpen’ but actually it’s really just taking out some of the rounded over cutting edge apex. I’ve drawn this sketch to explain what’s happening on a small scale, this will help you understand the function of a honing rod and how to get the best out of it.

You can see from the sketch that the very apex of the cutting edge it gets rounded over with use, the harder the material you are cutting the quicker that edge will ’round over’. What the Honing Rod or Steel does is get the round overs to stand back up restoring the cutting edge. Well, that is partly restoring it. You’ll never completely restore the edge but it goes some way into doing this. This is why they are used during the process of doing the work. It’s a kind of temporary fix until you can re-profile the cutting edge back to it’s optimum geometry. If you go to a family butcher you might see the butcher use the Steel hanging from his apron just before he cuts a nice piece of Fillet Steak. It gives him a nice clean cut.

What Materials are Honing Rods made from?

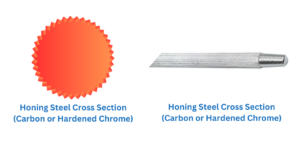

These are the most common honing rods and probably the oldest in design and manufacturing. It is produced by selecting the right kind of steel, in this case High Carbon Steel. It’s heated to forging temperature and then rolled in a machine to form these long fine ridges that form the apexes which will eventually do the work of re-aligning the edge. Just like any hardened steel product they are worked into their final shape etc.. and then hardened in a heat treat process.

You can see from this cross section what’s going on in the manufacturing process. It has these little apexes running along the length of the rod. By rubbing the cutting edge along it we can straighten out the rounded over sections and to some degree bring the edge back to a functioning blade.

Hardened Chrome honing rods are very similar in their design and manufacture but have used a carbon steel with plenty of the element Chromium in it. I would, at least, choose a Hardened Chrome Honing Rod.

There are something different entirely. They are made from a variety of materials but mainly Zirconia or Alumina, these elements are very hard and durable, hence the ability to help straighten the rounded over blade edge.

They are produced by shaping the ceramic material into their final shape, and just like a carbon steel product they are hardened in a kiln. We know a ceramic product is ‘fired’ and left to cool as you would a ceramic plate for example. This ‘fired’ rod is then the finished honing rod after it has a handle added. They are used in exactly the same way as a carbon steel one is used.

They are produced by shaping the ceramic material into their final shape, and just like a carbon steel product they are hardened in a kiln. We know a ceramic product is ‘fired’ and left to cool as you would a ceramic plate for example. This ‘fired’ rod is then the finished honing rod after it has a handle added. They are used in exactly the same way as a carbon steel one is used.

These are among the most expensive. The process to create one of these honing rods is different again. What they are is a base material that the Diamond Particles are fixed to. The base is usually a metal one and one which is also pretty hard carbon based metal.

The Diamond Particles can be fixed using various methods. Chemical or Vapor deposition can be used. However Electroplating is probably the most common way to do it. Put simply this process is created whereby the base metal is placed in a liquid containing diamond particles which have been suspended in it. Once an electrical current is passed through the liquid the diamond particles will adhere to the base metal surface.

The Diamond Particles can be fixed using various methods. Chemical or Vapor deposition can be used. However Electroplating is probably the most common way to do it. Put simply this process is created whereby the base metal is placed in a liquid containing diamond particles which have been suspended in it. Once an electrical current is passed through the liquid the diamond particles will adhere to the base metal surface.

It then goes through a process of polishing to achieve the surface smoothness or grit they are after.

Seeing as these are much smaller than a kitchen knife it makes sense to get hold of a small one to keep in your camping bag for use in the field. Something like this one is perfect, I have one myself. This one is the ‘Accusharp Diamond’ pen style, check it out for yourself here.

If have a close look at the video above, you can see the motion he uses to hone his knife.He takes his time and runs the blade down one side and then the other. As the knife moves down the rod he draws it across the rod. It’s because the rod is on an angle he can draw the knife across it rather than straight down it.

Sometimes it only takes three or four strokes either side to get that slight edge he’s after. Other other times he might give it ten or twenty strokes until he’s happy with it.

It does take a bit of practice but what this fella is doing is the correct way to learn. Once you have learnt and doing it right you can then try other ways to do it to find the perfect way for you.

Intro.

To date there have been no less than 15 Sprint Models, 4 have been discontinued. Of the 11 there are 4 select models, 3 classic models, 3 Ops models & 1 called Copper Sprint. Now there is this new Ops model which is a Jade color so this makes 16 current Sprint models available. Of these 16 models the steel ranges from 420 stainless to CPMS30V to CPMS45VN.

Specs.

Blade.

It has a black Cerakote drop point blade with a little dip in the spine making it recognizable as a Sprint model. At 7.6 cm it’s a bit small for me and I hate Cerakote blades but it does lend itself to better corrosion resistance and wear.

Blade Steel:

This model is made from CPM S30V. Made by Crucible Steel it’s a budget steel but one that’s pretty rare in that it’s made for cutlery. Having said that plenty of known manufacturers use it like Spyderco, Benchmade, Chris Reeve, Cold Steel, Kershaw and of course Buck use it. There are plenty more who use it but just know it’s a steel made for making knives. It takes an edge very well but the compromise is that edge retention isn’t quite so good.

Weight.

Seeing as it’s a small knife it’s very light at 3.55 oz, you hardly know you have it in your pocket.

Handle Material.

Good old G-10 prevails. It’s one of these slightly opaque Jade colors, I don’t really like it but looks striking up against the black blade. You can’t really go wrong with G-10, it’s hard wearing and will probably outlast the blade!

Pocket Clip.

Apart from being a deep carry the only thing worth mentioning with the pocket clip (and the pivot pin and the screws) is that that it’s also black in color, assume it’s Cerakote and nice to have them matching the carry clip.

Locking Mechanism.

Another liner lock mechanism, arguably the most popular locking system placed on knives. Depending on the quality of the build will determine how effective the liner lock is. After a fair bit of wear they can become ‘unlocked’, watch out for that on your old knives!

Conclusion.

I am a big fan of Buck knives but this one doesn’t do much for me. I’m sure it has the build quality we know to trust from such a maker. It has ball bearings for a smooth operation flipper. You can do all the usual things with such a knife like one handed open and closing. The deep carry clip keeps the knife out of the way but in easy reach. I guess it is pretty unusual looking blade. It’s listed at just under US$120 on the Buck website.

If you love this little blade why note grab one for yourself direct from the Buck website.

If you are interested in spending around US$100 I’d go for something like this MKM knife with a way better Bohler M390 blade steel, and it’s under US$100!

As always, happy camping :0)